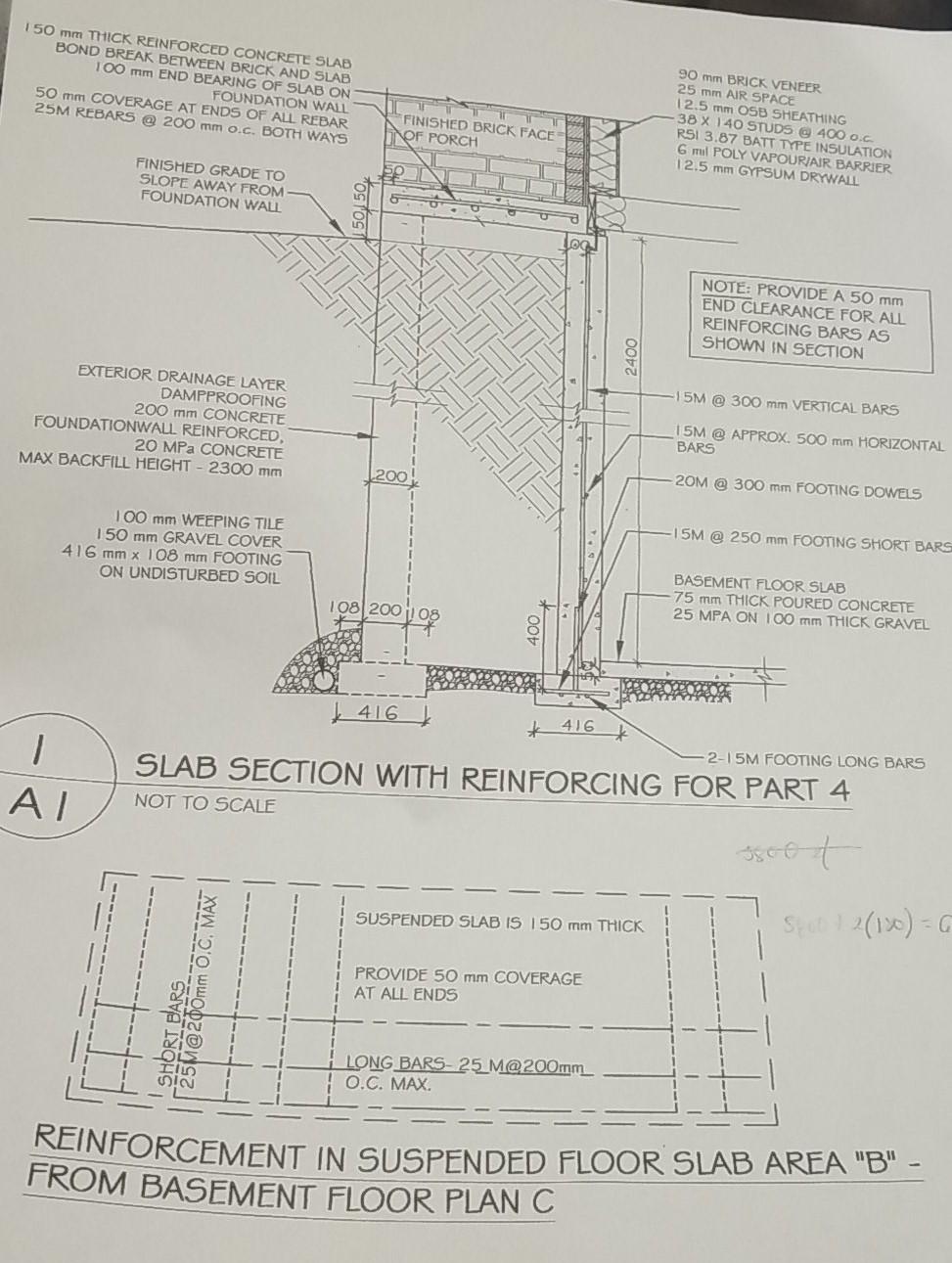

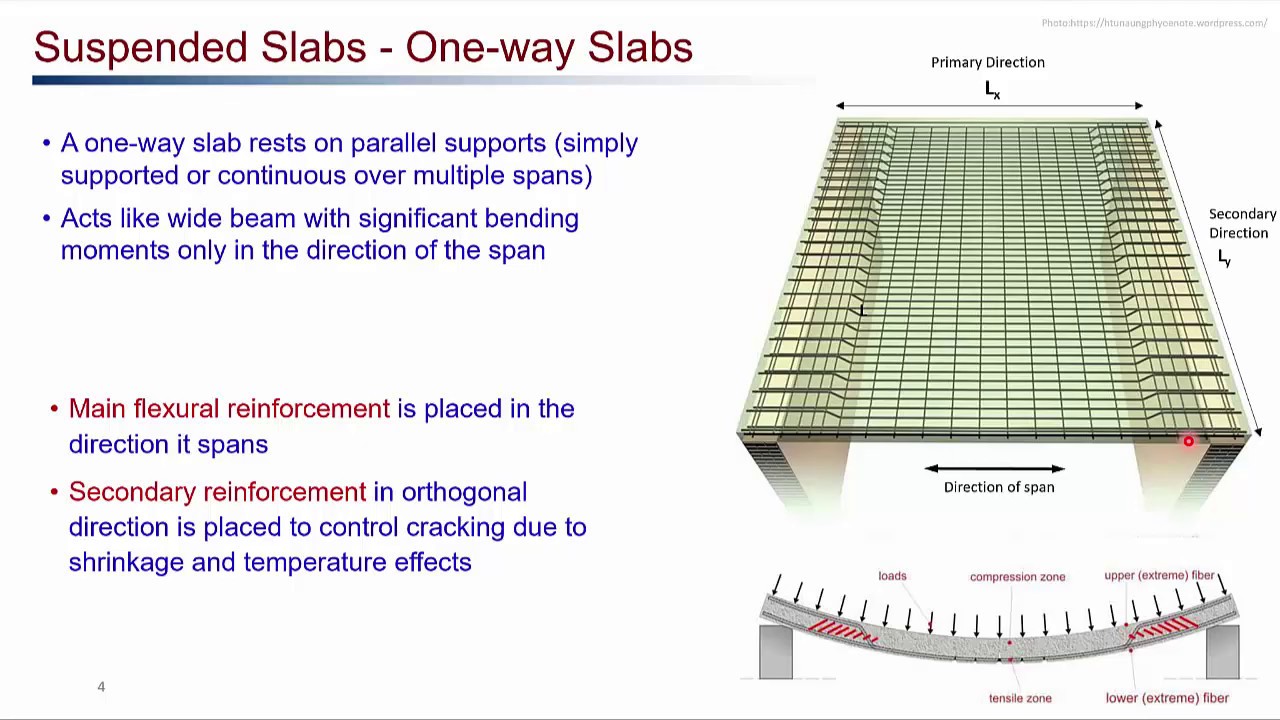

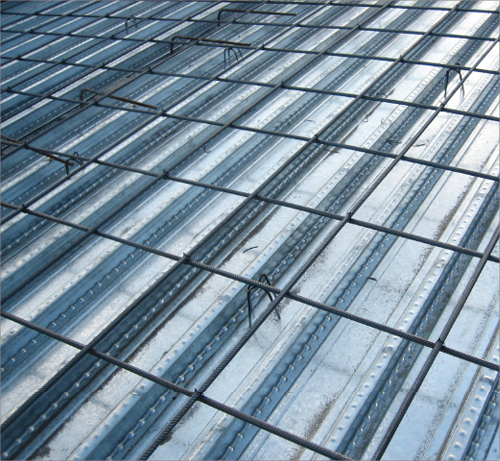

The concrete slab requires a minimum compressive strength of 25MPa (30MPa for carparks) in 28 days Steel mesh reinforcement is placed at minimum cover, (according to durability requirements NZS 3101 Section 311) primarily for crack control caused by shrinkage during curing Guidance on crack widths tolerances is given in NZS 3101 and Hera report R4113Reinforcement Estimates Typical average weight of reinforcement (kg/m3) in concrete building elements The below figures are for guideline only and may vary for different projects Ribbed floor slabs Slabs – one way Slabs – two way Stairs Tie beams Transfer slabs Walls – normal Walls – wind 135 1100 0 Reinforcing bars or posttensioning will keep cracks tight in suspended slabs Because of differences in the type of reinforcement used, crack widths in concrete on metal decks vary Some designers

Concrete Slab Wikipedia

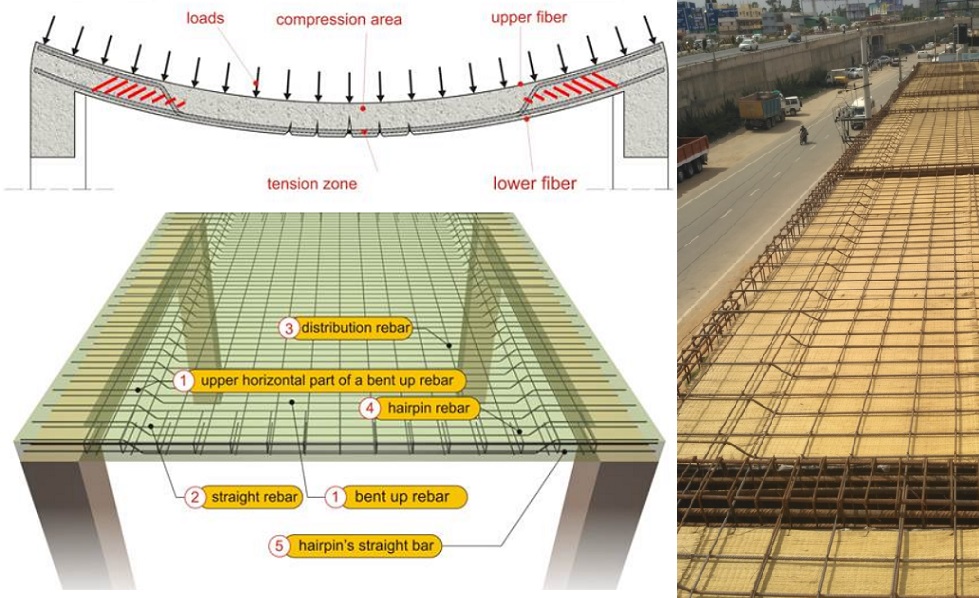

In a suspended slab reinforcement should be placed in

In a suspended slab reinforcement should be placed in- Provide cover blocks for slab and beams Fix the beam reinforcements Anchored into the columns Check reinforcement size and number as per design schedule Bottom reinforcement to be lapped within 1/3 beam span from supports only Check clear cover at beam bottom as well as the sides Top reinforcement Lap within midspan only (Lap at positiveSome contractors find that embedding the ma f CONCRETE FLOOR AND SLAB CONSTRUCTION 3021R39 terials and restraightening can be accomplished in one step 871 Bonded monolithic twocourse floors—For these using a modified highway straightedge floors, the topping course is placed before the base course 9

Concrete Floor Slab Construction Process The Constructor

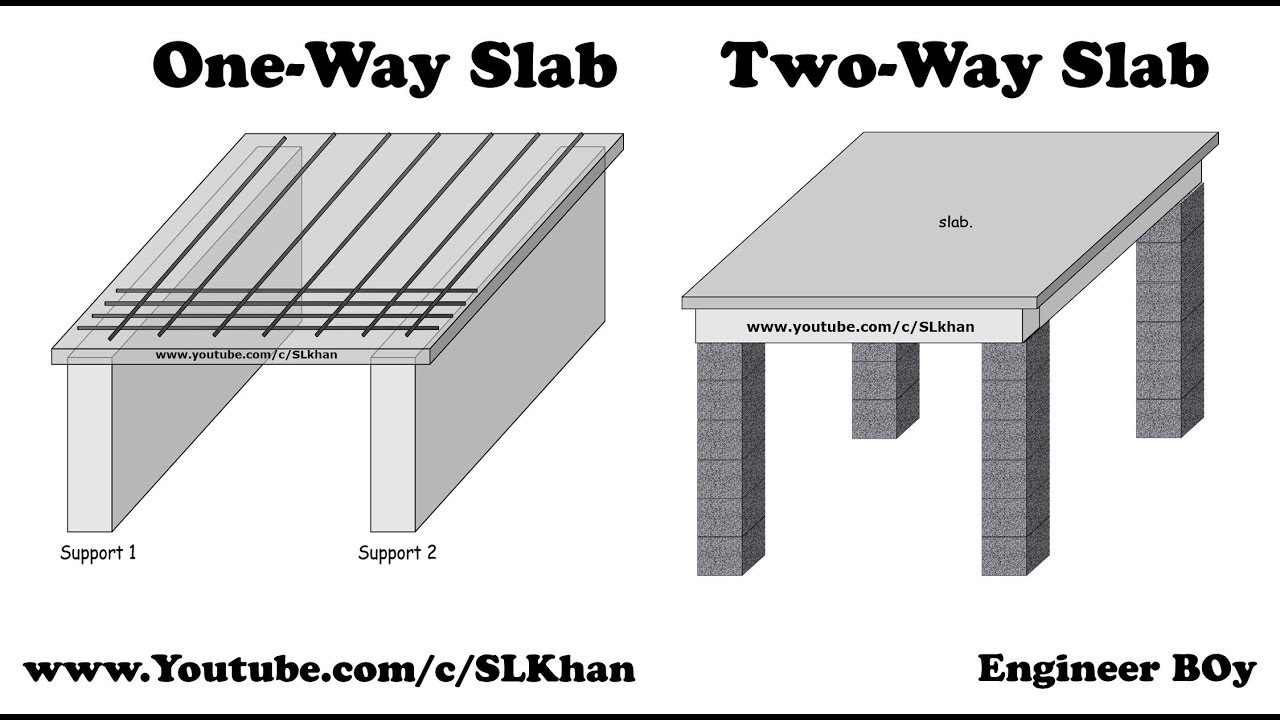

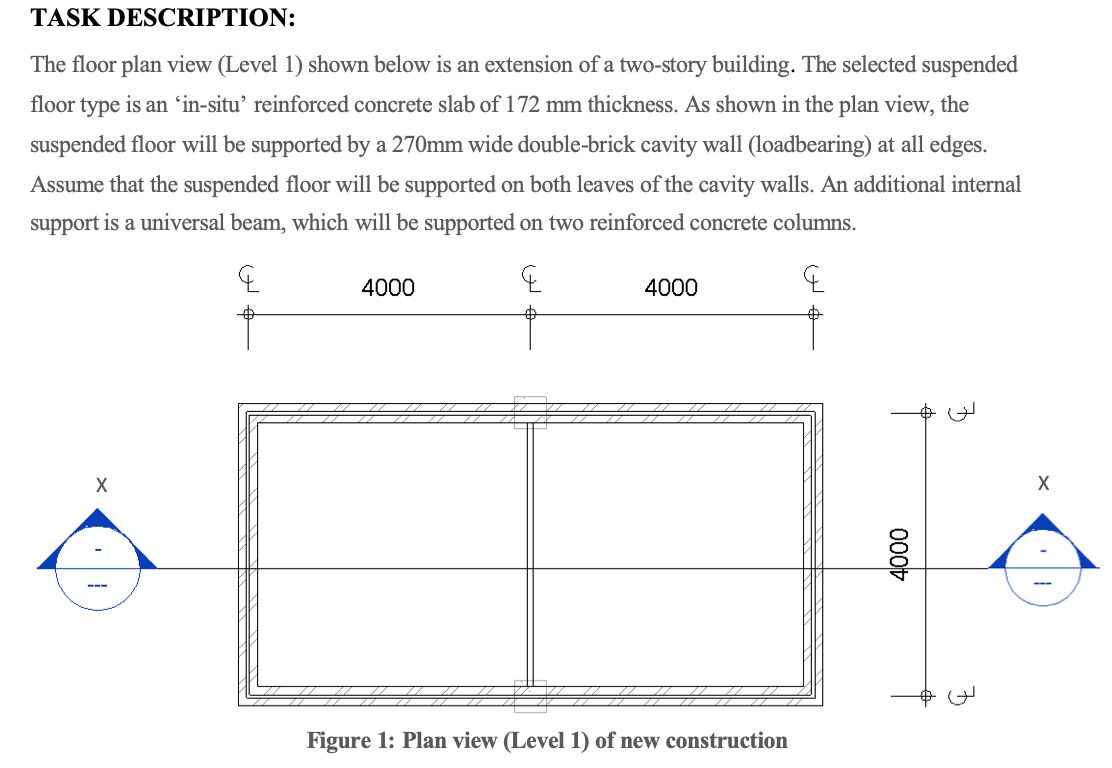

This chapter gives guidance on meeting the Technical Requirements for suspended ground floors including those constructed from insitu concrete precast concrete timber joists 521 Compliance 522 Provision of information 523 ContaminantsOne Way Slab Bar Bending Schedule Calculation Step 1 FIrst, find number of rods required for main reinforcement and distribution Number of Required Bars Formula = (Length of slab / spacing) 1 Number of Main Bars = Ly / spacing 1 = (4000/150) 1 = 27 nos Number of Distribution Bars = Lx / spacing 1 = 3000/150 1 = 21 nos Reinforced concrete slab & Suspended slabs construction A concrete slab is a very important structural element of your house and provides a flat, usable service to build on A suspended slab is a slab that has at least two of its opposite edges supported by walls, beams or columns and are not in direct contact with the ground

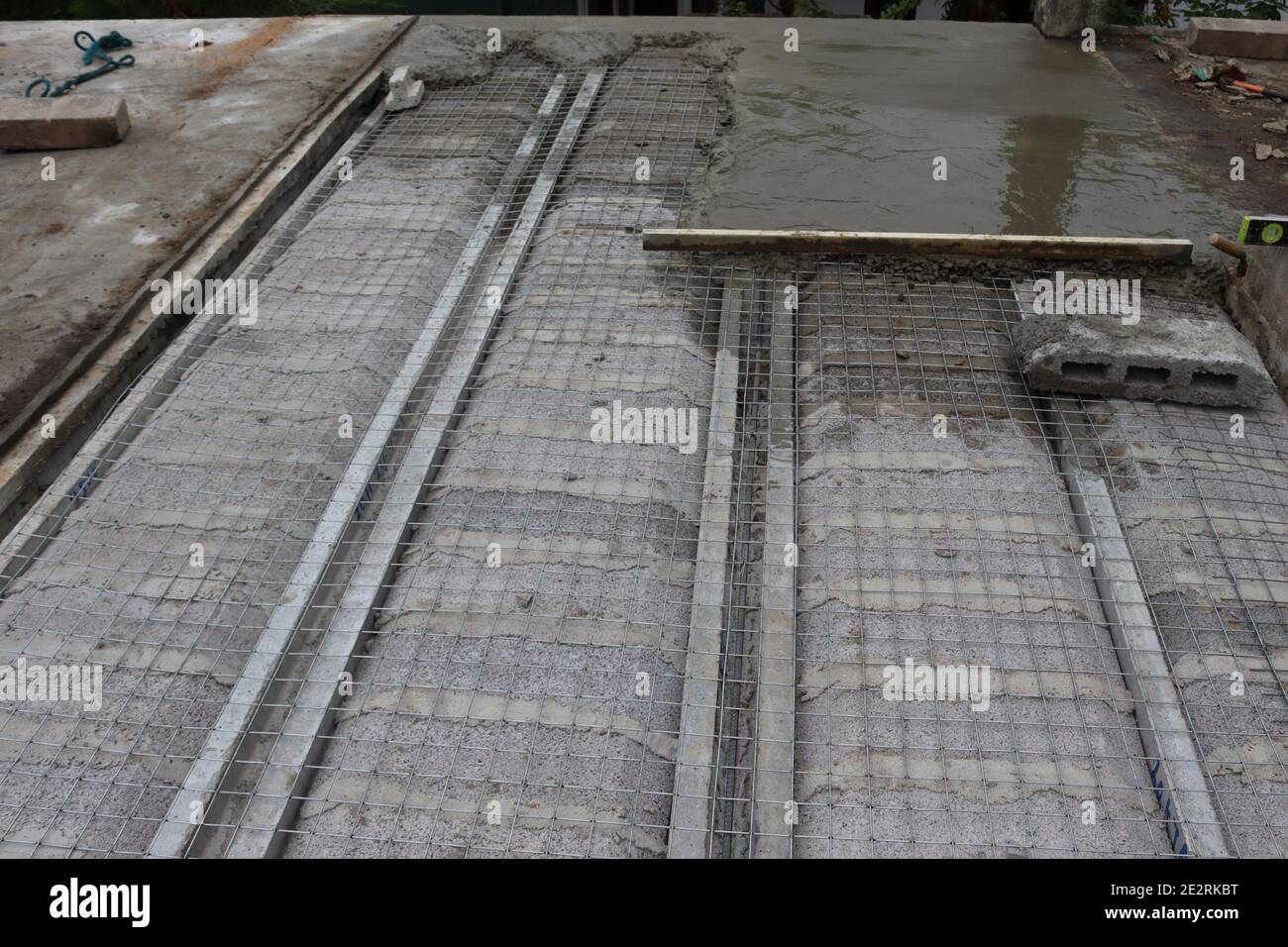

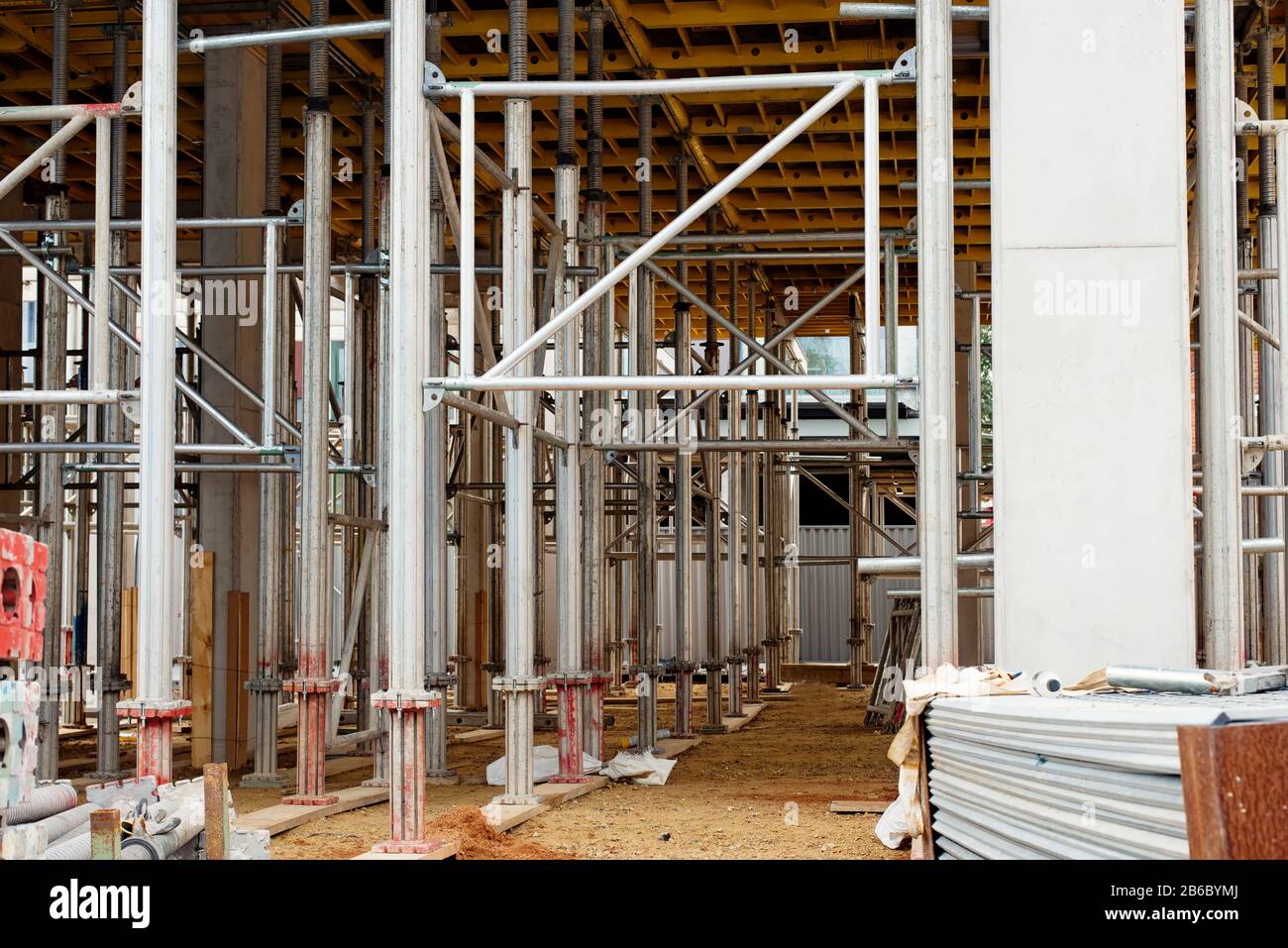

Suspended slabs are made of concrete and steel mesh, the same as a ground slab They are normally prefabricated offsite, and transported by truck Some slabs have hollow channels running through them these 'hollow core slabs' are used to help reduce weight, and also to allow cabling and piping to be run through the slab A long run of trench drain on a suspended slab poses some problems For one, saw cutting a long strip of floor to install a drain might weaken the whole floor Make sure that the floor has the necessary reinforcement or structural support to endure the new opening Any irregularities shall be immediately actioned This method statement describes the working procedures for suspended slab and all related activities This will include formwork, steel reinforcement work, scaffolding, propping / back propping, concreting works and removal of forms, props, scaffolding & support

Shrinkage and curling in slabsonground Refer to the latest edition of ACI 224R for a detailed discussion of cracking in reinforced and nonreinforced concrete slabs This guide describes how to produce highquality concrete slabsonground and suspended floors for various classes of service It emphasizesSuspended slab reinforcement Crane bases, column pads, elevator pads Bridges / Under passes / Tunnels Ship wharf walls / Lot walls / Tanks Wind Farm Bases / Substations Concrete slab Suspended slab formwork and rebar in place, ready for concrete pour A concrete slab is a common structural element of modern buildings, consisting of a flat, horizontal surface made of cast concrete Steel reinforced slabs, typically between 100 and 500 mm thick, are most often used to construct floors and ceilings, while

Reinforced Concrete Slab High Resolution Stock Photography And Images Alamy

Structure Magazine Recommended Details For Reinforced Concrete Construction

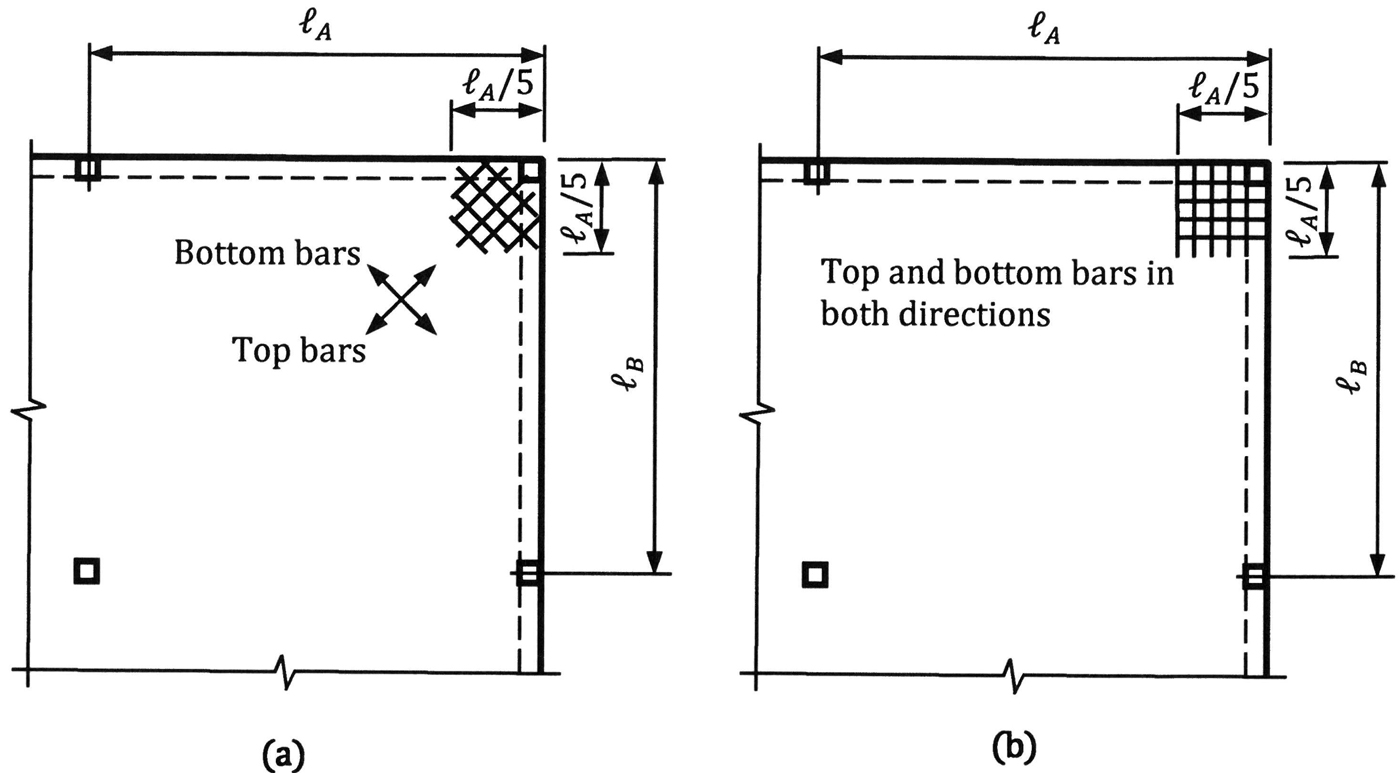

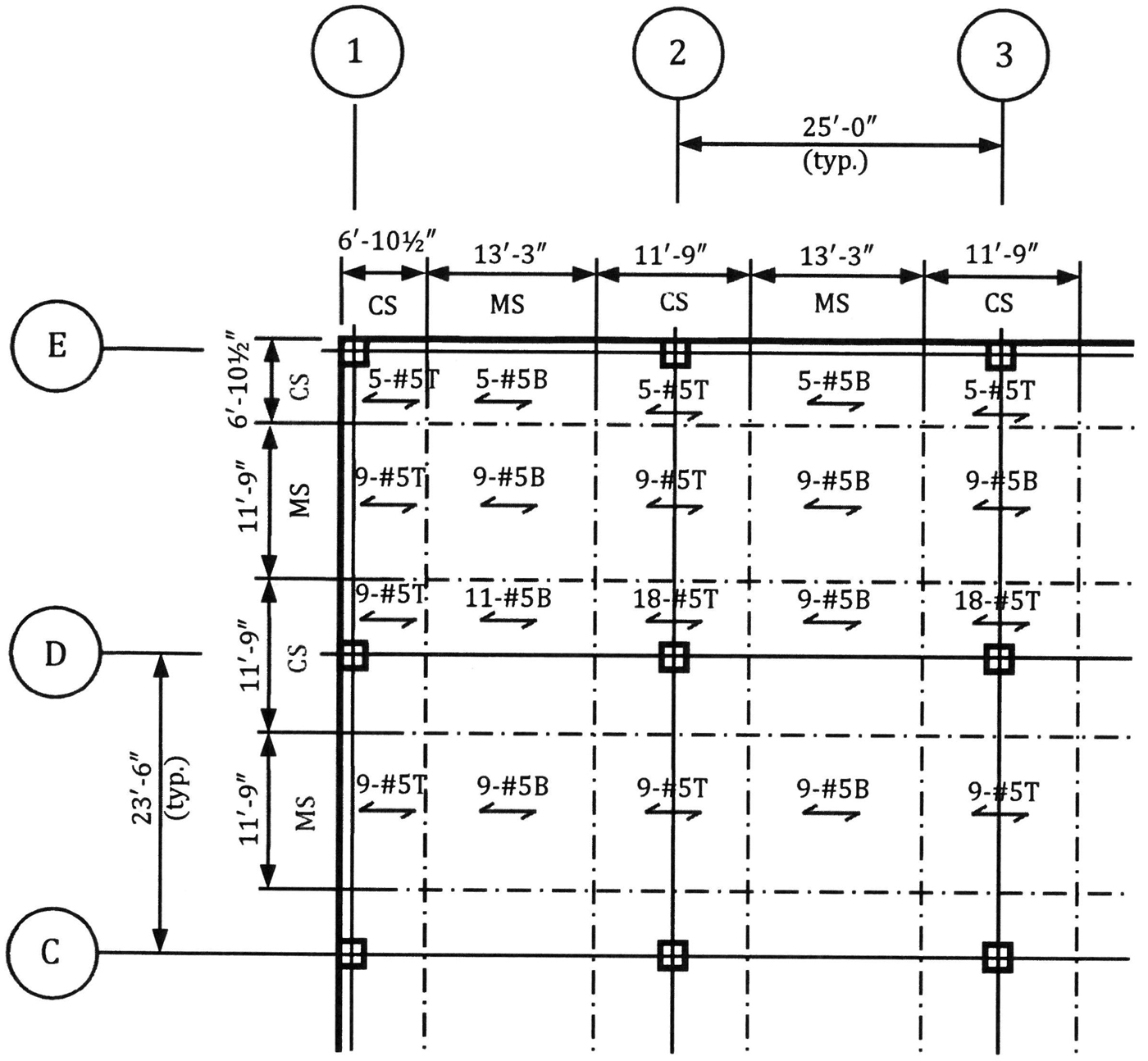

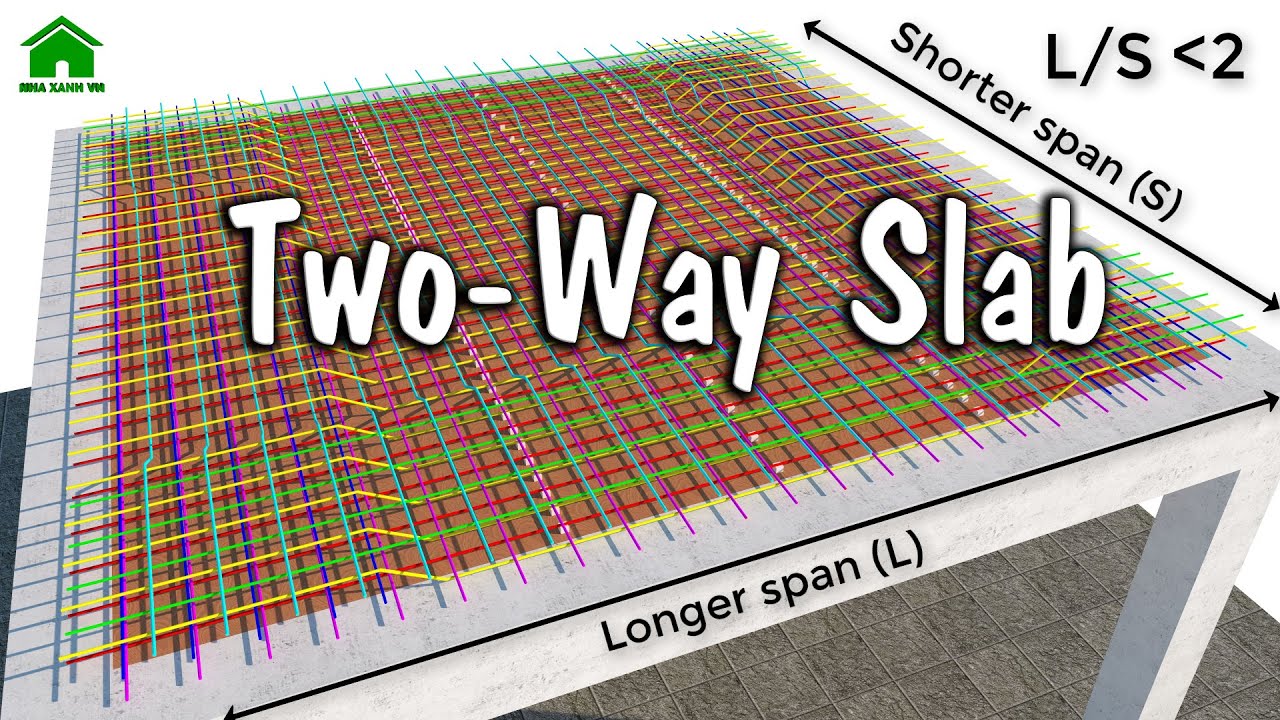

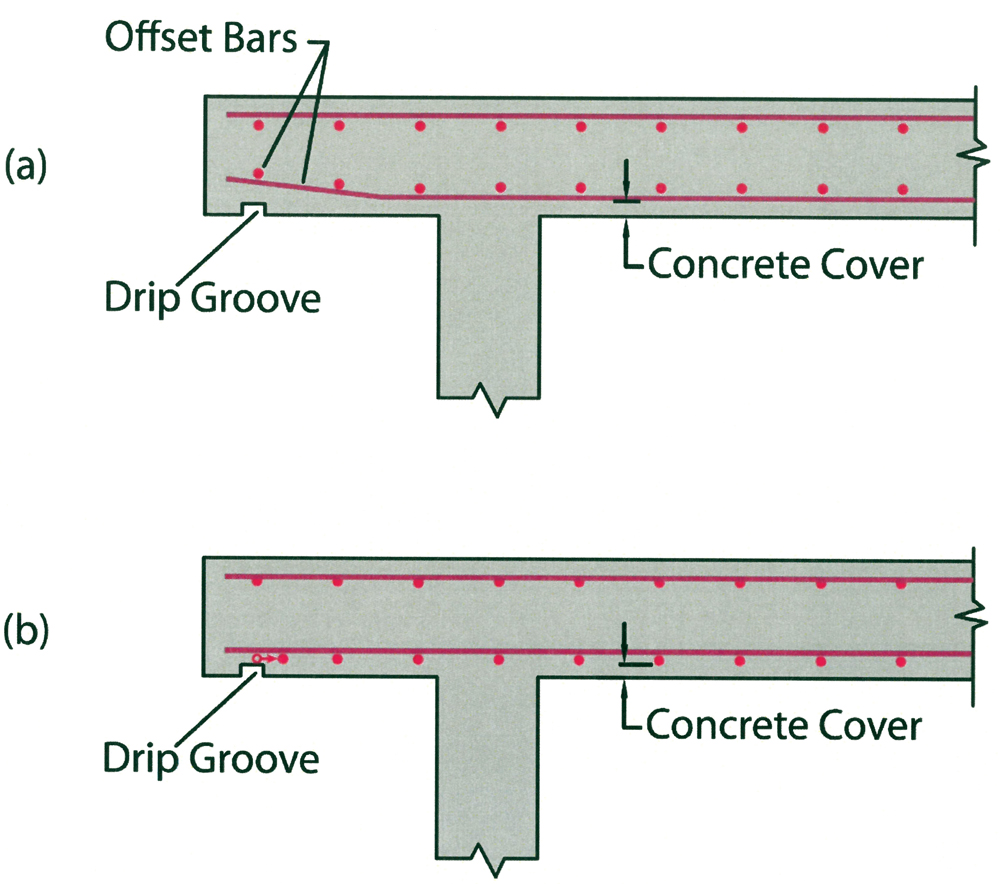

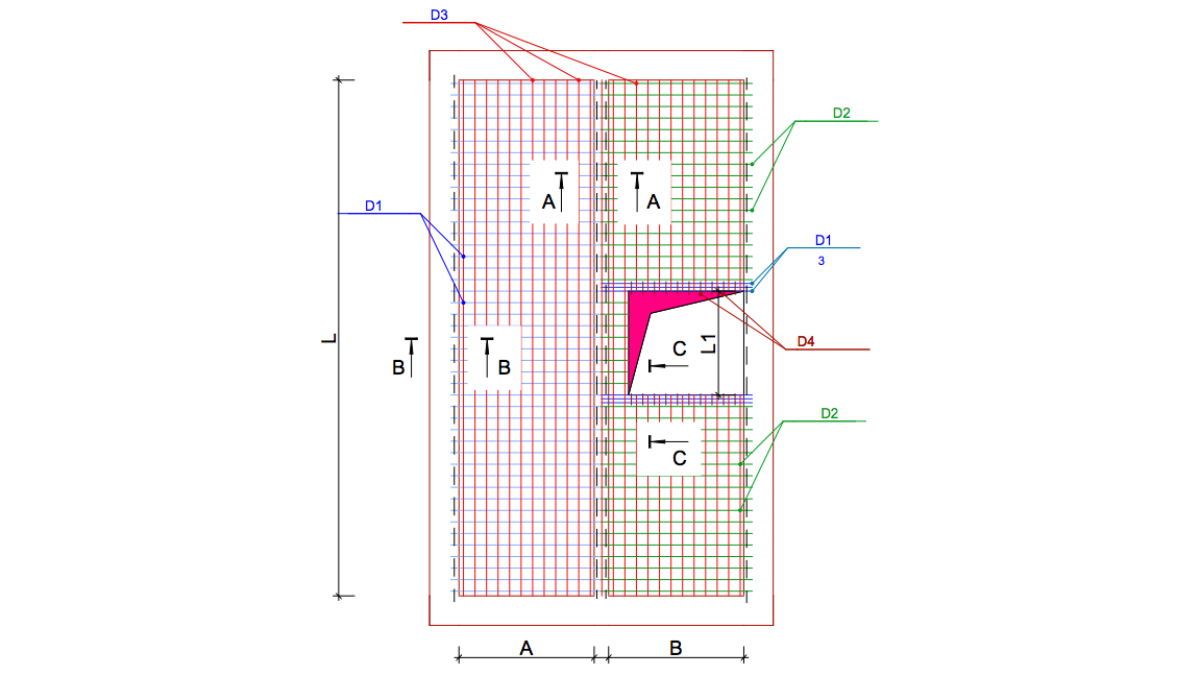

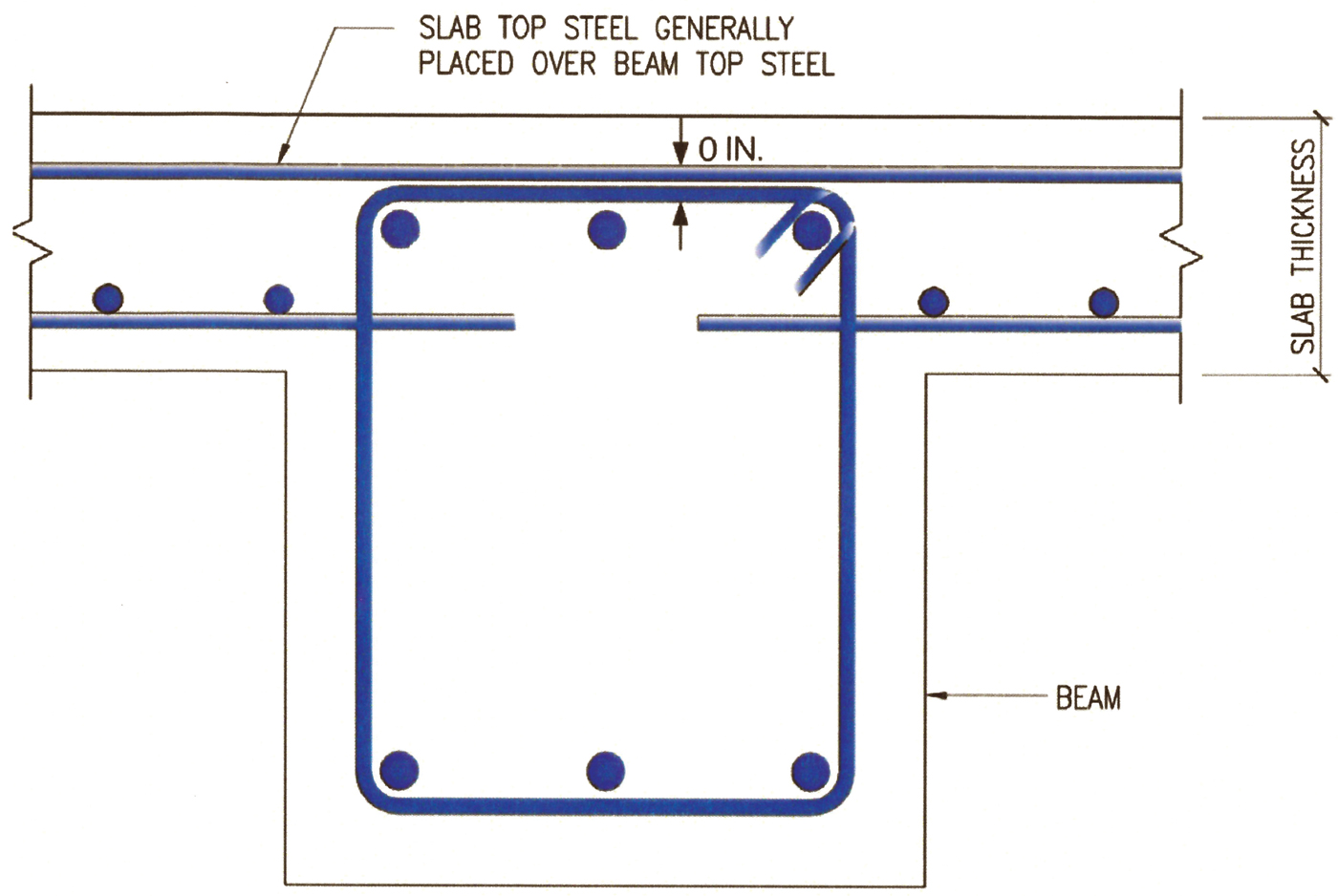

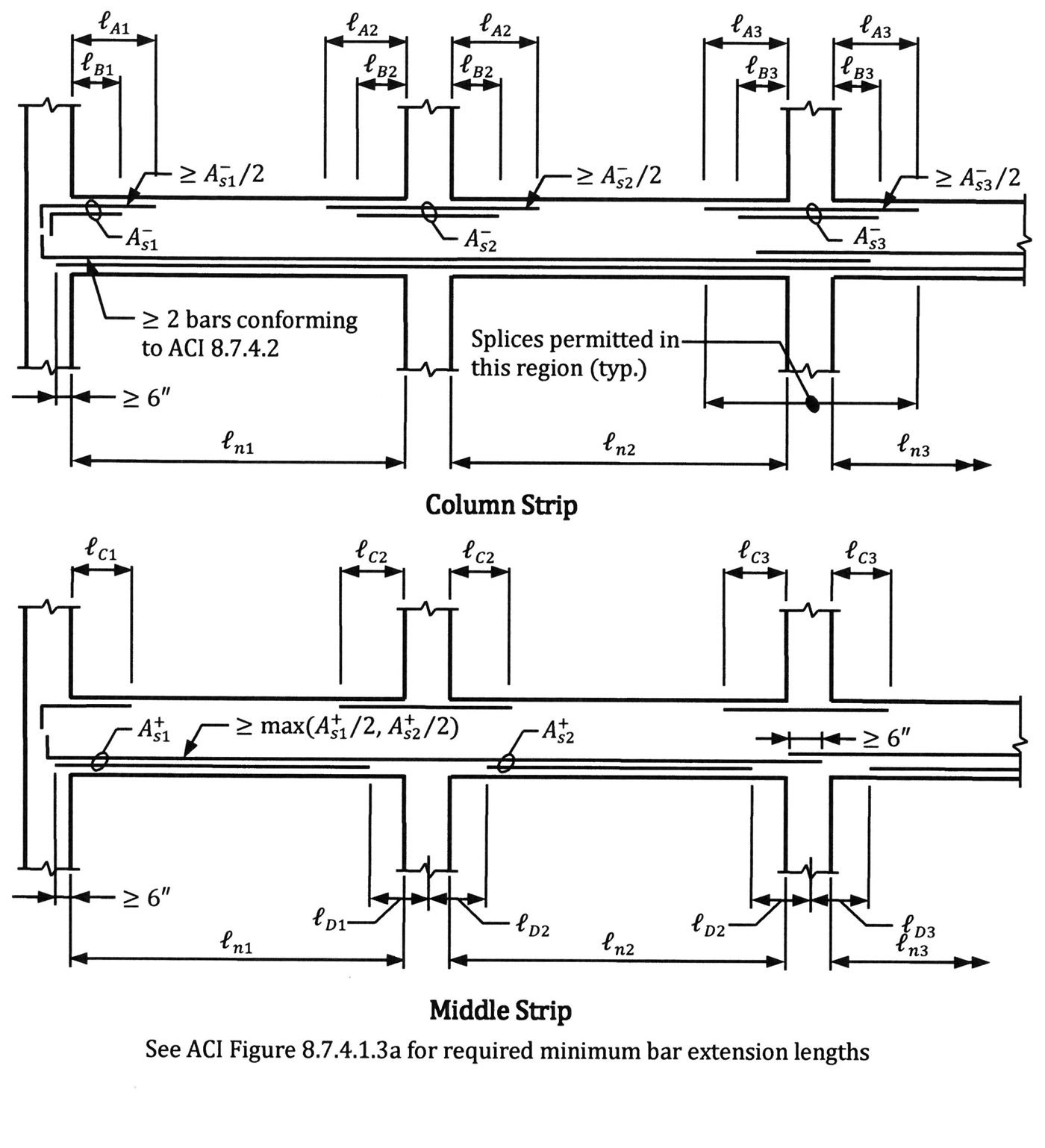

Further, slab reinforcement will be obstructed by the beam reinforcement, and they won't be able to place as considered in the calculation Therefore, it is very very difficult to achieve these requirements Thus, limiting the thickness to 105mm is a practically difficult task In this background, the widely used concrete slab thickness is 125mm Composite Concrete/Steel Slab is a slab where steel decking acts as nonrecoverable formwork and partial reinforcement for the floor slab The decking spans one way and will usually be continuous over several supports Single spans are, however, common and acceptable Support is as for insitu floors Precast Concrete Suspended SlabThis article is the first in a series on recommended reinforcement details for castinplace concrete construction Twoway slabs are generally defined as suspended slabs where the ratio of the long to the short side of a slab panel is 2 or less In twoway construction, load transfer is

Concrete Suspended Beam And Slab Construction Process Steel Rebar Reinforcement Placement Formwork Youtube

How To Reinforce Concrete Slab On Ground To Control Cracking For Construction Pros

A corrugated suspended reinforced concrete slab is made using a combination of steel and concrete Concrete is poured onto a strong steel tray, which gives it added strength for use in building or other construction purposes The tray will have a corrugated design The corrugations will run across the short dimension from end toConstruction sequence Questions send it to megadethigorot@gmailcom (No need to subscribe or comment if you don't want to ask in public just send a messagWelcome back to Green House Construction!This channel shall be replaced Nha Xanh E&C Channel instead Please follows me "SUBSCRIBE" this channelTWO WAY SLAB

Building Guidelines Drawings Section B Concrete Construction

Notes Engineering Reinforced Concrete Slab Design

RE suspended slab reinforcement detail KootK (Structural) 6 Jun 19 30 I have many, and varied, thoughts on this 1) I used to work for a structural firm that had a rather notable and charismatic founder It predates me but, on many occasions, I heard tales of him walking around to supervise engineers and whacking them on the wrist with aPrecast suspended slabs are constructed by pouring the slab in a formwork on the ground and then lifting the slab into its suspended position in the structure Formwork is installed on top of the struts and beams Reinforcement is assembled on top of the formwork Concrete is then poured into the formwork 1 Reinforcement Details of Simply Supported Beam and Slab As seen in figure1 below, for a simply supported beam and slab, 100% reinforcement as per the design is provided as tension reinforcement at the mid span of the beam and slab, and 50% is curtailed at the distance of 008L from the center support 2

One Way And Two Way Slab Youtube

Concrete Slab Wikipedia

While making structural drawings of the reinforced concrete slab, the slabs are abbreviated to "rcslab" or simply "rc" What are the Design of various types of Slabs and their Reinforcement ?Suspended Concrete Slab Suspended concrete slab is referred to a cement slab that is not in contact with the ground This type of concrete slab construction requires different concrete slab design from the one we normally see that is cast on the ground The most common application of suspended slab in residential construction is used at garage floor where below the garage floorΣAtr = crosssectional area of the transverse reinforcement along the development length Lsyt ΣAtrmin = crosssectional area of the minimum transverse reinforcement, which may be taken as 025As for beams and 0 for slabs As = crosssectional area of a

Quality Construction Of Suspended Floors Concrete Construction Magazine

Question 17 Refer To The Relnforcement In The Chegg Com

For a suspended slab, there are a number ofA concrete slab is a common structural element of modern buildings, consisting of a flat, horizontal surface made of cast concrete Steelreinforced slabs, t Suspended slab formwork is formed and cast onsite, and this is done with removable or nonloadable formwork s or permanent formwork s that form part of the reinforcement Therefore, to produce a suspended slab formwork, we need precise formwork, which can be selected from two different types

Suspended Slab And Beams Method Of Construction Constructupdate Com

Building Guidelines Drawings Section B Concrete Construction

Prior to the placement of reinforcement for concrete floor slab construction, inspect and check forms to confirm that the dimensions and the location of the concrete members conform to the structural plans Added to that, the forms shall be properly cleaned and oiled but not in such amount as to run onto bars or concrete construction joints Vertical placement tolerance for reinforcement in slabsonground is ± 3/4 inch from the specified location For slab thicknesses 12 inches or less, the concrete cover tolerance is Suspended Slabs are typically buildup in two ways 1 Precast concrete Unlike onsite concrete pouring, a leading manufacturing approach is used to produce highquality precast concrete in a restrained factory environment The reinforcement is placed in reusable and adjustable molds, and the concrete is poured, vibrated and cured

Concrete Slab Wikiwand

Reinforced Concrete Slab Design Guidelines The Constructor

I started a thread a couple of years ago seeking some advice on the relationship b/w the overall length of a suspended slab and the need to provide movement joints (link provided herewith for those interested) however I was more interested in understanding if it would make a difference to the level of reinforcement if you had a longThe Insudek suspended slab consists of the following components Lipped channels 150/225/300mm wide x 60mm high with Prefixed reinforcement spanning between RC beams, structural steel beams and/or load bearing brickwork are spaced at 650/725/800 c/c – limiting steel fixing on site The slab is designed as simply supported or continuous ribs Reinforcing steel must be secured to prevent displacement during construction activities and concrete placement This is usually accomplished with tie wire Tie wire comes in 3 or 4pound coils Wires are placed in a wire holder or a reel is suspended from the worker's belt for accessibility The wire is typically 16½ or 16gauge black

Structure Magazine Recommended Details For Reinforced Concrete Construction

Installation Of Rebar For 2 Way Suspended Slab Youtube

4 Slabonground floor/footings 41 The Function of Footings 42 Footing Types 43 Slab Design 44 Construction Issues and Maintenance 5 Suspended Floors 51 Types of Suspended Floors 52 Terminology and Design Principles 53 Design Procedure 54 Insitu Concrete 55 Composite Concrete/Steel (Permanent Steel Formwork) 56 Precast Concrete 12 Beam and Slab Works Once the ground floor columns have been cast, it is time to prepare the project for beams and suspended slab reinforcement activity Like any other structural members, beams and slab reinforcement should be followed strictly Concrete slabs are rectangular, reinforced concrete structures that can be sized in length and width, but have a smaller depth They are used for floors, roofs and bridge decksYou can choose from many different designs for a suspended slab to

The Falsework Decking System Legs For Construction Of Suspended Reinforced Concrete Slab Stock Photo Alamy

Sunken Slab Detailing Structural Engineering General Discussion Eng Tips

, 0235 PM Re Suspended slab over porch The length of each porch is 50 ft, width (actual span across foundation walls) is 6'7" Thickness will be 4" Reinforcement will be wire In the calculations I've done, I'm assuming 50 lb/ft^2 for the slab dry weight (based on aGet One Month FREE at LinkedIn Learninghttps//bitly/2Zq5t95Full Learn To Read Structural Drawing Course at the cheapest ratehttp//bitly/2Xw0dkvThis vide Thickness of the slab is decided based on span to depth ratio specified in IS Minimum reinforcement is 012% for HYSD bars and 015% for mild steel bars The diameter of bar generally used in slabs are 6 mm, 8 mm, 10 mm, 12mm and 16mm The maximum diameter of bar used in slab should not exceed 1/8 of the total thickness of slab

Suspended Slab Reinforcement Detail Structural Engineering General Discussion Eng Tips

This Is Everything Inside A Suspended Slab That A Lot Of People Do Not See We Have A Concrete Beam To The Middle Left Han Storey Homes Ideal Home Construction

So maximum diameter of reinforcement bar used in 4 inch (100mm) thick RCC slab is 16mm (5 soot) if thickness of slab is 6 inch (150mm),then maximum diameter of bar used in rcc slab is 150/8 which is equal to 1875mm 1875mm bar not available, So maximum diameter of reinforcement bar used in 6 inch (150mm) thick RCC slab is mm (6 soot)

Structure Magazine Creating An Opening In Existing Floors

Ground Slab Steel Reinforcement Detail Site Process Concrete Spacer Suspended Ground Slab Works Youtube

Roof Structure Structural Engineering Concrete Slab

Suspended Concrete Slab Suspended Slab Cement Slab

Reinforcement Detailing Of Reinforced Concrete Slabs The Constructor

Design Of Reinforced Concrete Slabs Video 1 Youtube

Suspended Ground Floor Slab Reinforcement Avi Youtube

What S Possible With Suspended Slabs On Metal Deck Concrete Construction Magazine

Building Guidelines Drawings Section B Concrete Construction

Types Of Slabs In Construction Different Types

Concrete Slab Abis

Al Yazeem General Contracting Suspended Slab On Grade Reinforcement Construction Contracting Formwork Scaffolding Reinforcedconcrete Abudhabi Uae Construction Building House Structure Structuralengineering Civilengineering Architecture

Structure Suspended Slab Home Building In Vancouver

Concrete Slab Floors Yourhome

How To Design One Way Slab As Per Aci 318 19 Example Included The Constructor

Structure Suspended Slab Home Building In Vancouver

What Is The Purpose Of Steel Reinforcement In A Concrete Floor Slab Quora

Concrete Slab Wikipedia

Design Of Reinforced Concrete R C Slabs Structville

Q Tbn And9gcs Jfito3osvkszwu Nlnbmliouqmfy 2pwavm Wfzs4k Cjzrf Usqp Cau

1

Reinforced Concrete Slab An Overview Sciencedirect Topics

Concrete Slab Floors Yourhome

Construction Joint In Slabs The Structural World

What Is Two Way Slab Design Reinforcement Details Green House Construction Youtube

Sbs Suspended Beam Slab Prestressed Concrete Slab System Stock Photo Alamy

The Device Reinforced Concrete Slab Basement Floor Download Scientific Diagram

Structure Suspended Slab Home Building In Vancouver

Structure Suspended Slab Home Building In Vancouver

How Are Suspended Slabs Built Build

Two Way Slab Proper Detailing Aci Concrete Code Issues Eng Tips

Floor Slab An Overview Sciencedirect Topics

Ground Slab Steel Reinforcement Detail Site Process Concrete Spacer Suspended Ground Slab Works Architecture

Frequently Asked Questions At First Floor Slabs

Zlabform Is The Newly Introduced Integrated And Insulated Reinforced Concrete Suspended Slab Flooring Passive House Design Architecture Building Construction

16 Different Types Of Slabs In Construction Where To Use

Concrete Floor Slab Construction Process The Constructor

5 Things To Look For When Inspecting A Suspended Concrete Slab

Detailing Of Reinforced Concrete Slabs Structville

The Falsework Decking System Legs For Construction Of Suspended Reinforced Concrete Slab Stock Photo Alamy

Structure Magazine Recommended Details For Reinforced Concrete Construction

Lightweight Suspended Concrete

Concrete Slab Wikipedia

Structure Magazine Creating An Opening In Existing Floors

5 Things To Look For When Inspecting A Suspended Concrete Slab

Reinforced Concrete

First Floor Concrete Slabs What You Need To Know Eco Built

Design Of One Way Slab Reinforcement Details Green House Construction Youtube

The Doren Home Suspended Garage Slab Plasti Fab

Building Guidelines Drawings Section B Concrete Construction

Builder S Engineer Suspended Ground Floor Slabs

Building Guidelines Drawings Section B Concrete Construction

Specialist Reinforcement Installed For Suspended Warehouse Concrete Floor Slab In Burton On Trent Level Best Concrete Flooring

What Are The Spacing Of Reinforcement Bar In A Suspended Slab 6mx4m Quora

Explain If The Suspended Slab Is One Way Or Two Way Chegg Com

What Is Steel Fixing Steel Fixing Is Shaping And Fitting The By Taha Ardati Medium

R Building Constructing Concrete Floor Slab Building Course Of Suspended Slab Formwork Metal Reinforcement Windown Installation Service

Monolitic Suspended Slab Eplan House

5 Things To Look For When Inspecting A Suspended Concrete Slab

Minimum Reinforcement In Slabs And Beams Online Civilforum

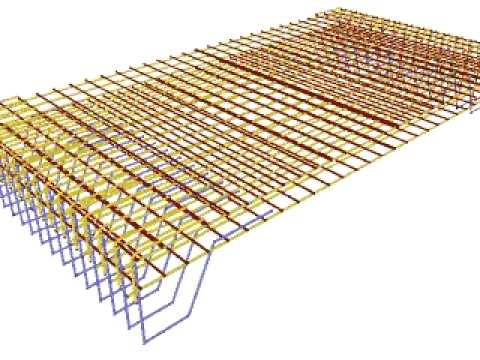

Suspended Ground Floor Slab Reinforcement 3d Warehouse

5 Things To Look For When Inspecting A Suspended Concrete Slab

Concrete Slab Floors Yourhome

The Falsework Decking System Legs For Construction Of Suspended Reinforced Concrete Slab Stock Photo Alamy

Xypex Xypex For Waterproofing Suspended Slab Concrete Xypex

Www Vsvu Sk Workspace Media Documents Reinforced Concrete Slabs 59ccc9a5d48c6 Pdf

3 531 Slab Reinforcement Photos Free Royalty Free Stock Photos From Dreamstime

Ground Slab Steel Reinforcement Detail Site Process Concrete Spacer Suspended Ground Slab Works Architecture

Structure Magazine Recommended Details For Reinforced Concrete Construction

Concrete Floor Slab Construction Process The Constructor

Www Vsvu Sk Workspace Media Documents Reinforced Concrete Slabs 59ccc9a5d48c6 Pdf

5 Things To Look For When Inspecting A Suspended Concrete Slab

Concrete Cover

Structure Magazine Recommended Details For Reinforced Concrete Construction

1

Concrete Cover

How To Calculate Steel Quantity For Slab Footing And Column The Constructor

Rbb Construction Ltd Preparation For Suspended Concrete Slab At Our Extension Installation Of Reinforcement Mesh And Bars

Concrete Rebar

3

Is Slab Placed Over The Beam Quora

5 Things To Look For When Inspecting A Suspended Concrete Slab

The Device Reinforced Concrete Slab Basement Floor Download Scientific Diagram

Expanded Polystyrene Eps Formwork Block Zlabform Zego Pty Ltd For Flooring Concrete Floor Slab Insulating

0 件のコメント:

コメントを投稿